Guiderail Asset Management Platform

New Jersey Department of Transportation

Markets utiltized:

Keywords

JMT Technology Group worked with the New Jersey Department of Transportation (NJDOT) to develop a comprehensive technology-based approach to inventorying and prioritizing guiderail assets within the department’s current jurisdiction. The approach was designed to support prioritization of guiderail upgrades and to support the NJDOT Statewide Guiderail Improvement Program.

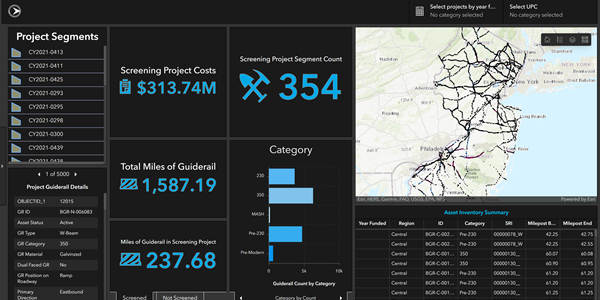

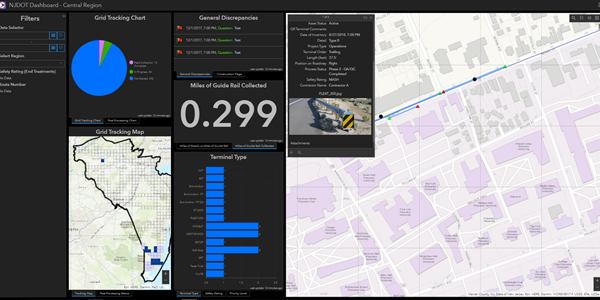

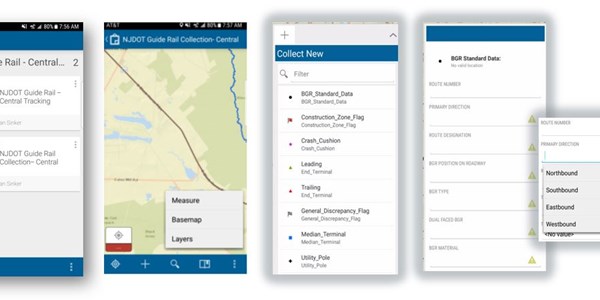

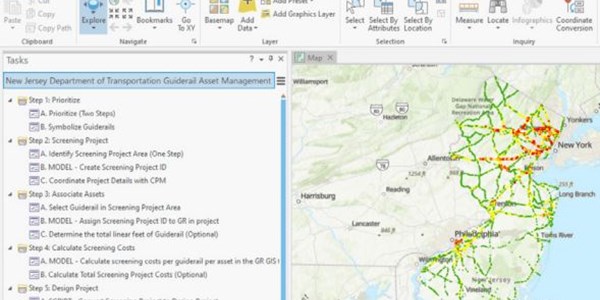

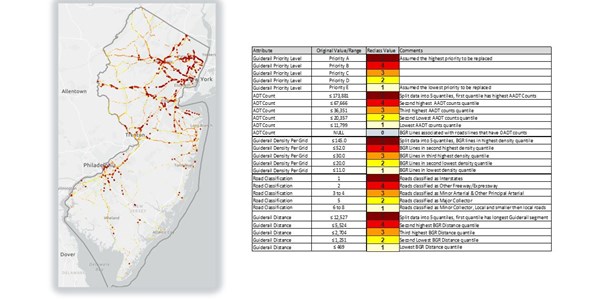

JMT Technology Group began by working closely with the department to review guiderail design criteria and identify the physical conditions to be collected. The goal was to document the existing physical conditions and warranting conditions associated with each guiderail assembly, which would then be used to assist in the prioritization of guiderail upgrades. To accomplish this, JMT Technology Group designed and implemented a solution using Esri tools and made it available to field collection staff, engineers, GIS experts, and project management staff. The online platform provided a unified environment to capture, manage, and report on the field collection process. The solution utilized a combination of ArcGIS Online, Web Map templates, ArcGIS Pro, Collector for ArcGIS, Data Reviewer, Model Builder, and Operational Dashboards to support effective management of the field assessment and data management operations. The resulting data was used to develop and prioritize guiderail replacement and maintenance projects.

The data included a comprehensive inventory of approximately 1,587 miles of guiderail across the 4,659 miles of state highway. This platform enabled staff to perform the work cost-effectively and accurately assess field conditions.

Using the platform led to greater efficiencies, consistent documentation, and provided an accurate assessment of guiderail conditions. The overall goal of the project was to establish a methodology that would allow NJDOT to assess the current physical conditions of each guiderail assembly and prioritize their maintenance and upgrades. The final prioritization methodology identified 12 high-priority replacement locations across the North, Central, and South Regions totaling 32 miles in length, which will optimize the use of the FHWA annual funding.